Standard Winch Features

This page describes the standard features included on most A.G.O. winches or available as options. Browse our Custom Winches portfolio for examples of special features and variations on these standard features beyond what’s shown here.

- Operation Controls

- Dog clutches

- Manual backup features

- Braking features

- Level winds

- Wire counting

- On-deck payload handling assistance

- Tension-limiting devices

- Winch-mounted A-frame boom

A.G.O. offers three standard operational control interface configurations:

1. “Simple” controls, with separate FWD/REV direction switch and speed knob (which may be directly integrated into KBRC-240D motor controller units as local controls for winches with up to 2HP motors)

2. Joystick controls with a combined speed-and-direction control two-way joystick

3. “Belly pack” controller with a joystick and integrated wire payout display (not compatible with all winch models), which includes a shoulder strap harness to hold the controller and leave both hands free for winch operation.

All wired remote controllers include emergency stop buttons. Controllers are typically implemented as wired remotes, but may be able to be implemented as local winch-mounted controls, or as a “dual-control” scheme where the active control can be toggled between the local controls and the wired remote controller.

Most standard A.G.O. winches incorporate a manually-actuated dog clutch into the powered drivetrain. Users can disengage the dog clutch to facilitate freewheeling drum payout or manual recovery, or engage the dog clutch to resume powered operations with the motor.

A.G.O. considers manual backup driving a critically important capability for all winches. Almost every A.G.O. winch includes some level of manual backup hand cranking features to ensure that users can still recover their payload, even in extreme power loss events.

Most winches facilitate manual hand cranking with the hand crank connected directly to the drum axle with no mechanical advantage. A.G.O.’s standard winches now also incorporate a “sprocket-assisted” manual backup auxiliary drivetrain to offer some mechanical advantage for manually recovering heavy loads.

Users can also optionally choose to incorporate a one-way drum ratchet that can be engaged to prevent the drum from unwinding out of control during hand cranking.

Most standard A.G.O. winches include a drum brake disk with manually-actuated brake caliper to control the drum speed during hand cranking and free wheeling, regardless of whether or not an electric brake is also present in the drivetrain.

The brake disk also includes holes along its edge for users to insert a pin to hard-lock the drum in place to hold loads during manual operations.

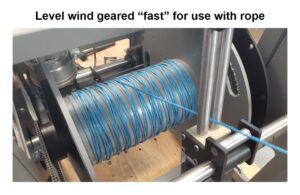

Level winds facilitate even spooling of a cable or rope across a drum to ensure predicatable winch performance and prevent excessive cable pileup and/or flange spill-over. They are important for maintaining a cable’s rated life or helping to prevent cut-in when used with rope.

(Note: “Perfect” levelwinding is difficult to achieve with mechanical sprocket-and-chain driven levelwind systems due to limited number of possible sprocket combinations.)

Some A.G.O winch models can have a drum-driven optical encoder integrated onto their frames and wired to a PLC unit with built-in display for cable payout and line speed measurements. The PLC may be mounted on the winch itself, integrated into a “belly pack” winch controller, or both.

The drum-driven encoder is required when used with a belly pack winch controller. Any winch models that cannot support a drum-driven encoder thus also cannot be used with a belly pack controller.

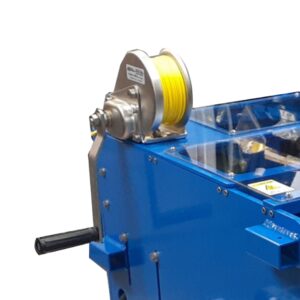

For added peace-of-mind when handling payloads on deck before fully deploying or recovering them from the water, users can opt to add a manual brake winch to the top of their winch.

The brake winch is loaded with ~30m of rope that can be connected to the payload, and will automatically hold loads unless it is being actively cranked to raise or lower the load. This offers precise payload control for improved safety during deployment and recovery on deck, and prevents the risk of the payload dropping suddenly in the event of any unexpected issues with the main winch or its power system.

Tension-limiting friction slip clutches can be conditionally* integrated into a winch’s main drivetrain to automatically prevent the winch from recovering loads beyond its rated pull capabilities. If loads exceed the slip clutch’s torque setting, it will slip and functionally disengage the powered drivetrain from driving the drum until the loads return within rated limits.

If loads cause the slip clutch to slip during towing or active recovery, the drum will slowly unwind until the tensions are relieved to within rated levels, at which point the friction slip clutch will automatically reengage the drivetrain and stop slipping.

A friction slip clutch is not an auto-rendering device. Friction slip clutches fall under the category of “Torque limiters” per UNOLS RVSS ed. 11 Appendix B.

* Due to the limited number of compatible sprocket sizes available for friction slip clutches, the drivetrain sprocket ratios required for some applications may not be able to facilitate the use of a friction slip clutch. If load limiting devices like a slip clutch are required for your application, let A.G.O. know and they will take this into consideration during the quoting process.

Winches for low-load applications with rated line pulls <~250lbs may be able to support using A.G.O.’s winch-mounted light-duty A-frame boom. It is a collapsible/disassembleable anodized aluminum boom assembly that mounts to the front of compatible winches to support a sheave in locations where an A-frame, crane, or other sheave support equipment may not be available.

Materials and Upgrade Options

Standard materials

By default, most A.G.O. winches are built with:

| Frames and drums | Aluminum 6061-T6, powder-coated with undercoat primer for marinization |

| Fasteners | 18-8 stainless steel |

| Mounted bearing units | Painted steel housings w/ steel bearing units, greased and coated with anti-corrosion spray |

| Sprockets | Steel, coated with anti-corrosion spray |

| Drive chains | Tsubaki Neptune corrosion-resistant plated steel, greased liberally |

Material upgrades

Certain materials can optionally be upgraded (for a fee) for customers that want increased corrosion protection.

| Fastener upgrade | 316 stainless steel |

| Mounted bearing units | Thermoplastic or stainless steel housings w/ stainless steel bearing inserts |

| Drive chains | Stainless steel |

A.G.O. does not make winches with stainless steel frames or drums.

Motors

A.G.O. designers will assess which HP motor your application requires when quoting. These are the default and available upgrade options for some common motors:

| 1Hp | 2HP | 3HP | 5HP | |

| Default | IP44 painted steel | IP44 painted steel | IP55 painted aluminum | IP55 painted aluminum |

| Upgrade | IP55 painted steel | IP55 painted steel | IP69K stainless steel | IP55 stainless steel |